Fluid-structure interaction

Interactions between air bubbles, liquid droplets and solid surfaces are ubiquitous in nature. Recent advances in micro/nanofabrication and chemical functionalization techniques has enabled the development of engineered surfaces whose wetting behavior deviates from the traditional and well understood Wenzel and Cassie-Baxter models. At ETL, we study complex bubble-droplet-surface interactions to better understand the underlying physics. We utilize the understanding gained from these studies to design engineering systems that can manipulate and utilize interfacial forces to create new functionalities and improve efficiency. Here, we also measure drop friction on well-defined micro-pillars and micro-holes using a cantilever force sensor that can measure sub-micronewtons force..

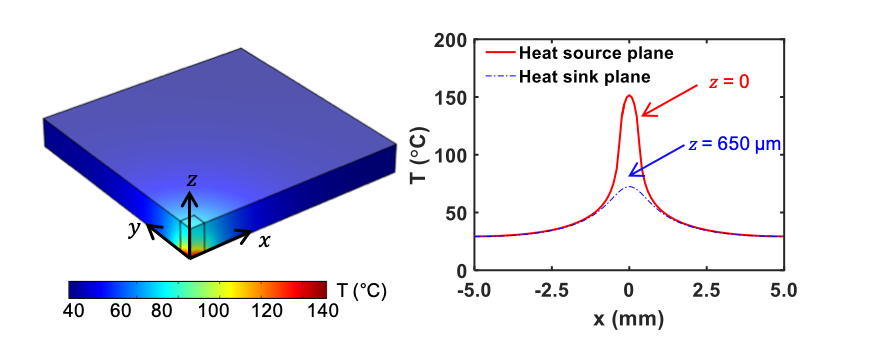

Thermal management

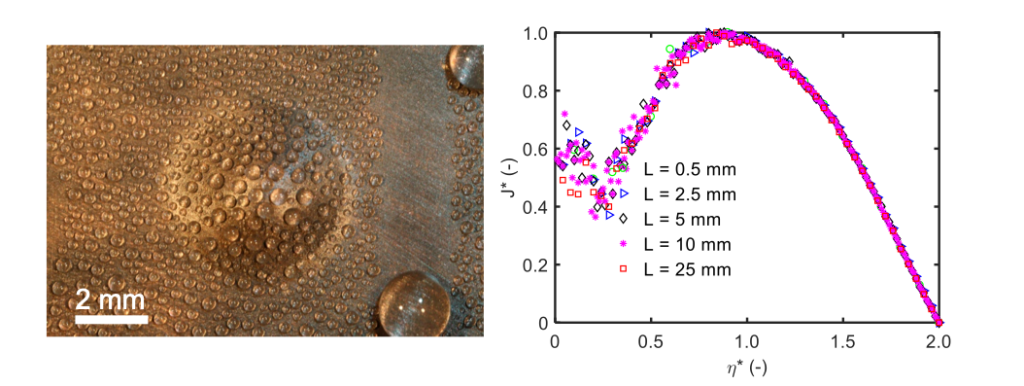

Silicon-based transistors (the switches that process data) on computer chips have roughly halved in size every two years (this is known as Moore’s Law), becoming faster, smaller, more energy efficient, and cheaper over the past five decades. The continued miniaturization over the decades has resulted in generating highly concentrated non-uniform (both in space and time) heating that exceeds 100 W/cm2. This trend has caused a severe thermal management challenge. Recently, thin-film evaporation has been demonstrated as a promising strategy to address the thermal management needs of advanced electronics and energy systems. At ETL, we study phase-change based thermal management solutions for cooling hotspots, which are highly nonuniform both spatially and temporally. Hotspots are highly localized regions with extreme heat flux and exceedingly high temperature.

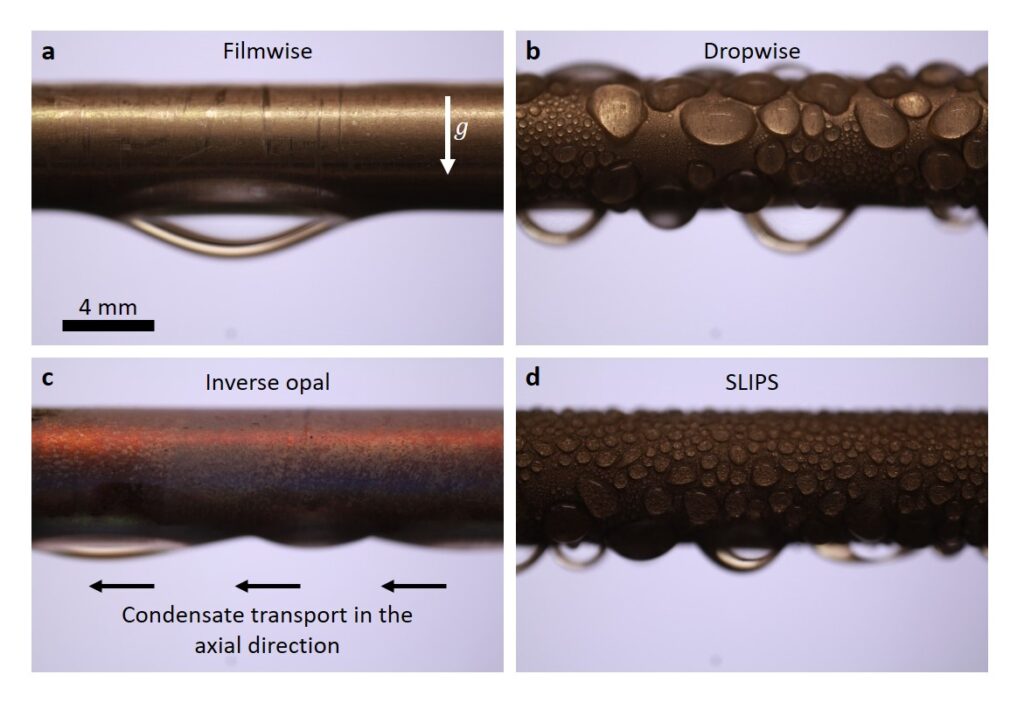

Condensation

Vapor-to-liquid phase change condensation is a ubiquitous phenomenon in industry. It is an important process in power generation, desalination, thermal management and environmental control. For example, the overall efficiency of a steam cycle, which accounts for nearly 85-90% of the global electricity production, is directly linked to the condenser where vapor changes phase to liquid water. Recently, micro/nanostructured surfaces impregnated with lubrication oil (also referred to as slippery liquid‑infused porous surfaces or SLIPS) have been demonstrated to improve phase-change condensation. At ETL, we seek innovative solutions to improve phase-change condensation of water and low-surface tension fluids.

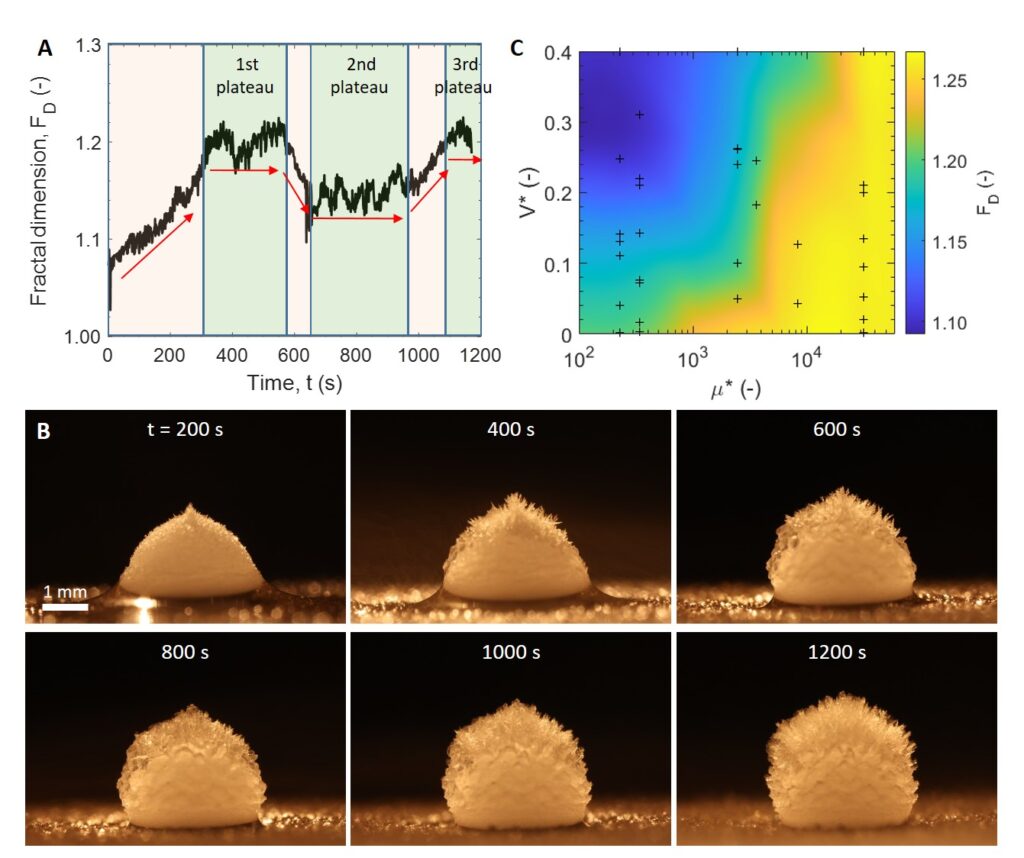

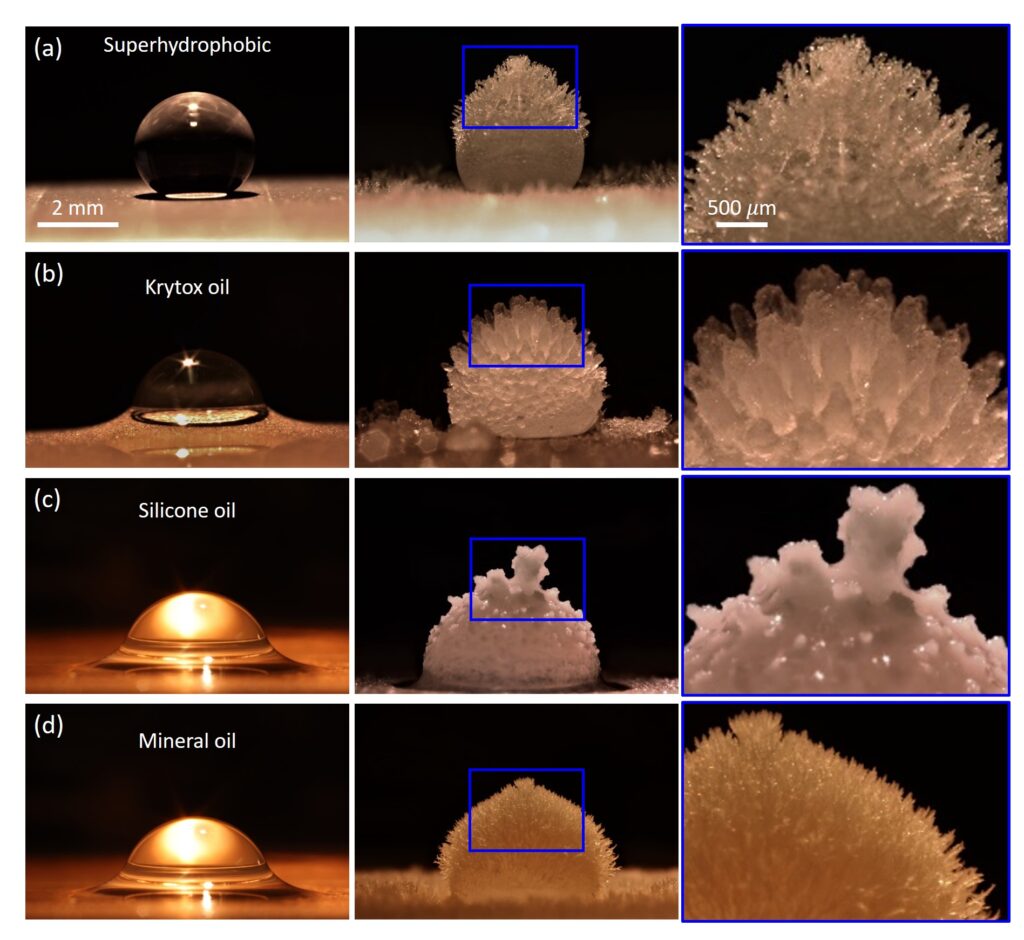

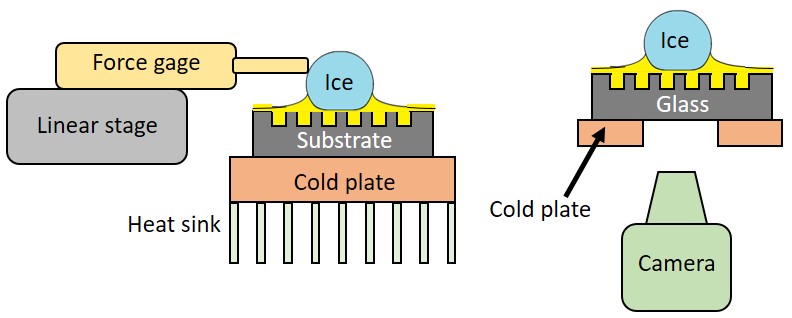

Icing/freezing

Ice formation and accretion cause safety risks in many applications ranging from power grid and satellite communication infrastructure to transportation. Understanding ice formation on cold surfaces is essential to address this issue. Oil-impregnated micro/nanostructured surfaces have been demonstrated to delay freezing and reduce ice adhesion strength. At ETL, we study condensation frosting on various surfaces.

Water harvesting

Water is an abundant natural resource that covers three-quarter of the earth’s surface. Despite this abundance, two‑third of the world’s population is experiencing water shortage. Drought and desertification are projected to worsen the global water scarcity. Countries that do not experience fresh water shortage currently may face the problem in the near future. Consequently, there is an urgent need for innovative solutions to the global water crisis. At ETL, we take inspiration from nature to rationally design materials to collect water from low relative humidity environments.

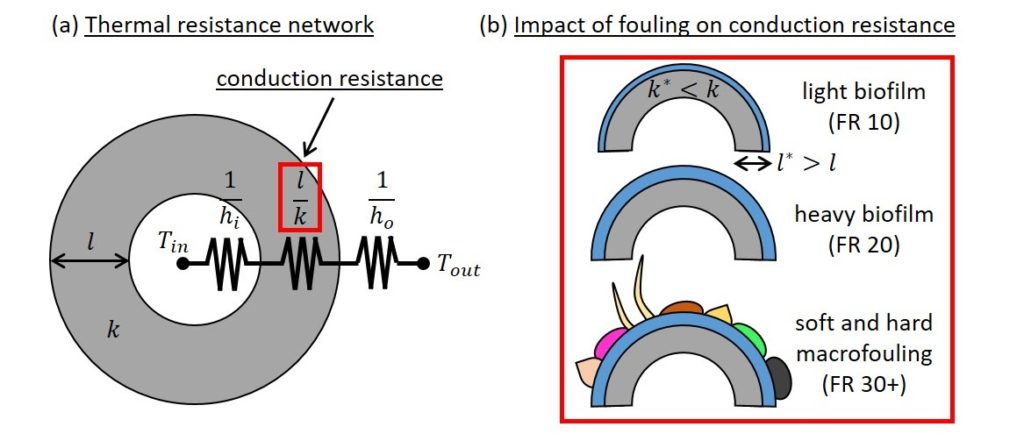

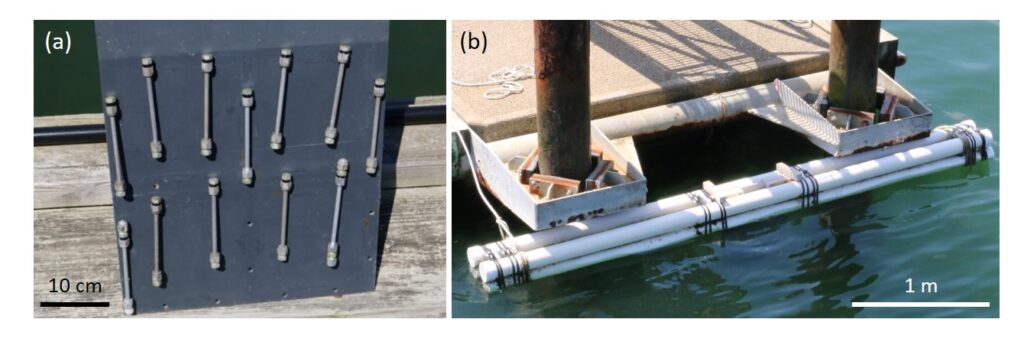

Fouling resistant heat exchanger design and characterization

The process of heat exchange between two fluids that are at different temperatures and separated by a solid wall (usually high thermal conductivity) occur in many engineering applications. The device used to implement this thermal energy exchange is commonly referred to as a heat exchanger, and specific applications may be found in space heating and air conditioning, power production, waste heat recovery, wastewater treatment, chemical processing, fluid separation, desalination, and food processing. Heat exchangers that operate in wet environments suffer from attachment of inorganic and organic fouling agents. Typically, fouling agents have low thermal conductivity, which decreases the fin efficiency by increasing the conduction resistance. In spite of its negative impact in heat transfer, fouling is one of the least studied topics in the thermal community. This work investigates fouling in heat exchangers and their negative impact in thermal transport and overall system efficiency. Additionally, we seek to mitigate the problem via novel material design.

Solar steam generation

Using the concept of interfacial heat localization, floating structures have been demonstrated to generate steam/vapor from salt water with solar-thermal conversion efficiency as high as 85%. This strategy has a potential to replace tradition thermal desalination plants and solar stills. The floating structures, however, suffer from accumulation of salt that reduces performance. At ETL, we seek to develop fouling-free solar vapor generators for water desalination.

Droplet impact dynamics

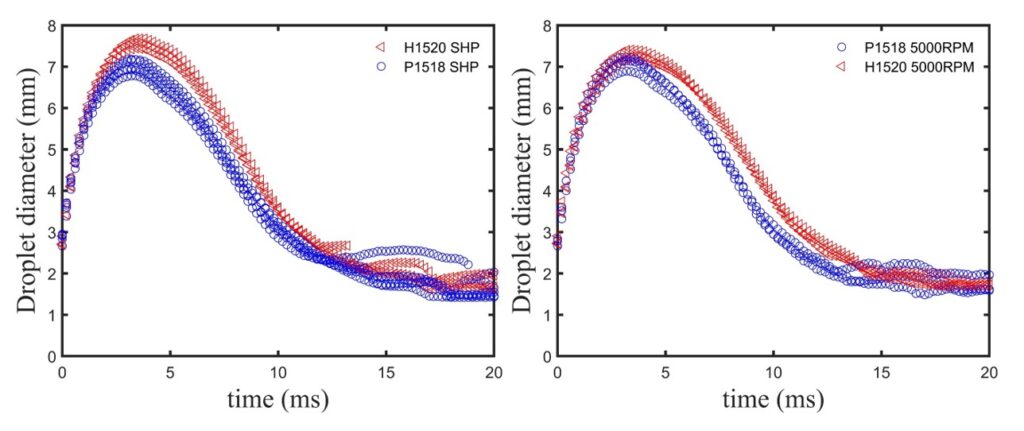

Water-repellent superhydrophobic (SHB) surfaces have many industrial applications including drag reduction, self-cleaning, anti-fouling, anti-icing, and condensate shading. However, despite their many desirable properties, SHB surfaces can lose their superhydrophobicity (transition to Cassie-Wenzel state) due to various conditions such as drop impact, drop evaporation, and drop impact. Recently, it was shown that hydrophobic micro/nanostructured surfaces infused with an immiscible viscous fluid can avoid these shortcomings. These surfaces, which are commonly referred to as slippery liquid-infused porous surfaces (SLIPS) or lubricant-infused surfaces (LIS), have low contact angle hysteresis that is credited to their repellency to a wide range of fluids. at ETL, we investigate the droplet impact dynamics on SLIPS.

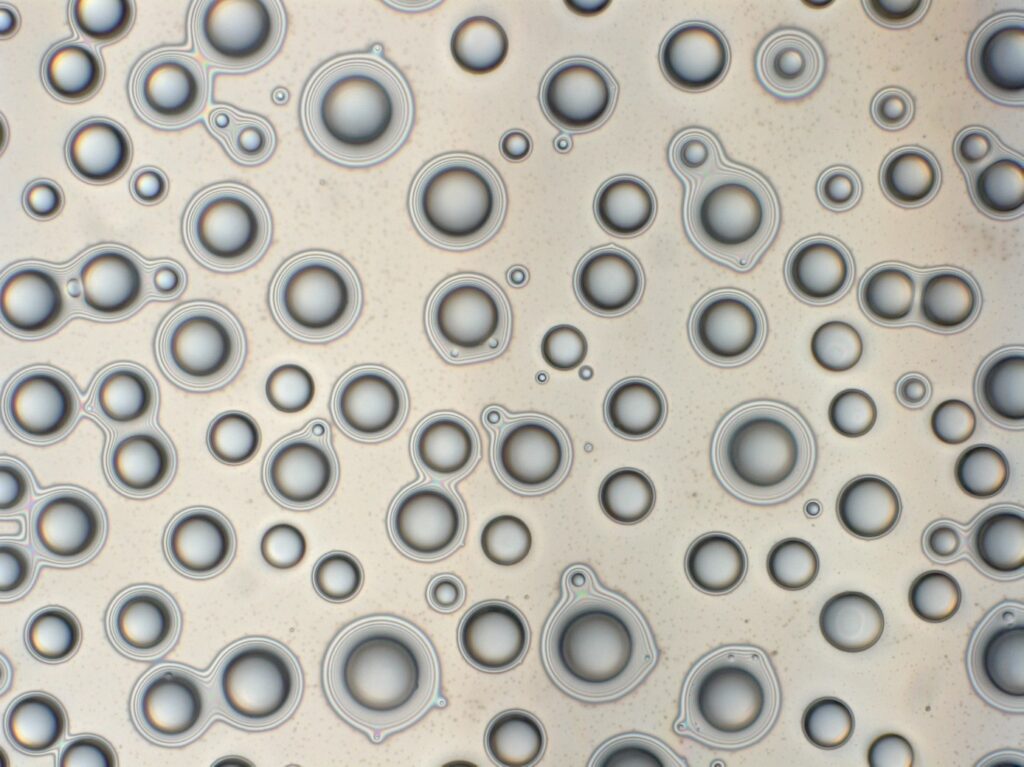

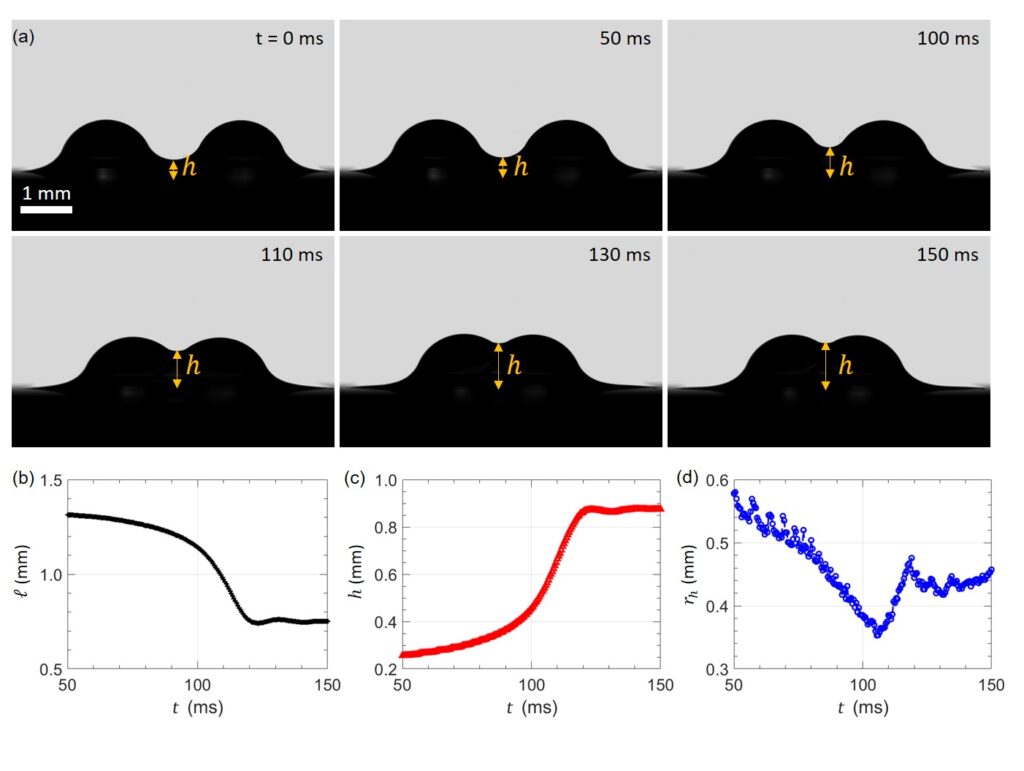

Droplet coalescence mechanism

Droplet coalescence is a common phenomenon in condensation heat transfer and water harvesting. In dropwise condensation, coalesced droplets are removed from the condensation surface by gravity. Slippery liquid-infused porous surfaces (SLIPS) or lubricant-infused surfaces (LIS) are a new kind of surfaces that have record-low contact angle hysteresis and have potential application in condensation heat transfer and water harvesting. Droplets sitting on SLIPS can interact with other droplets due to the existence of wetting ridge. The wetting ridge makes the droplet coalescence mechanism on SLIPS differ from other surfaces such as superhydrophobic surfaces. At ETL, we experimentally and analytically investigate the droplet interaction and coalescence on SLIPS.

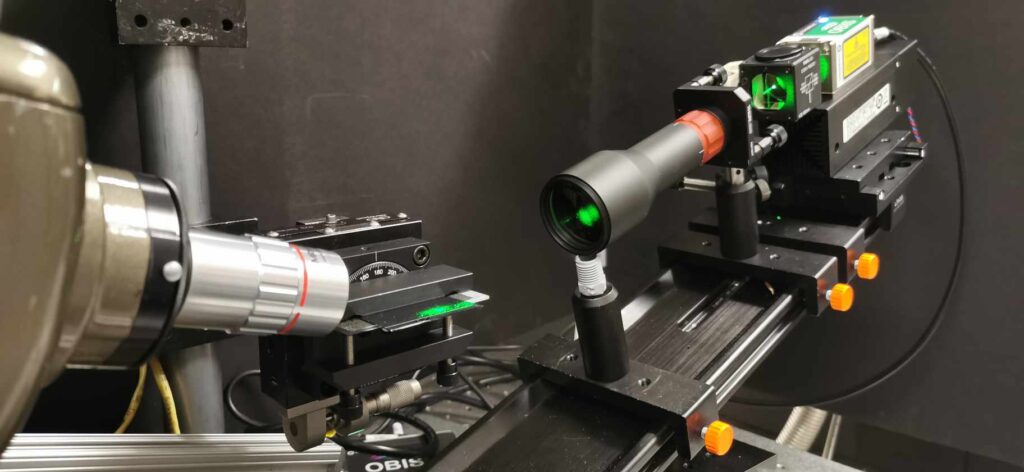

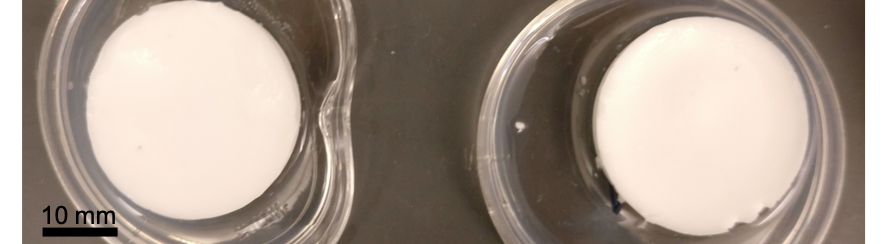

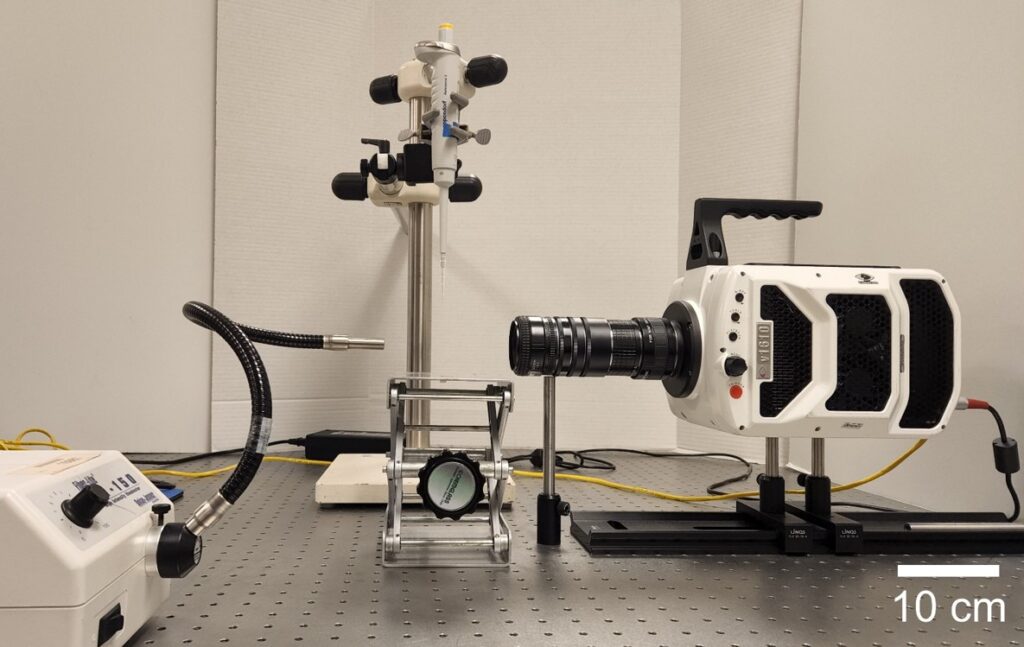

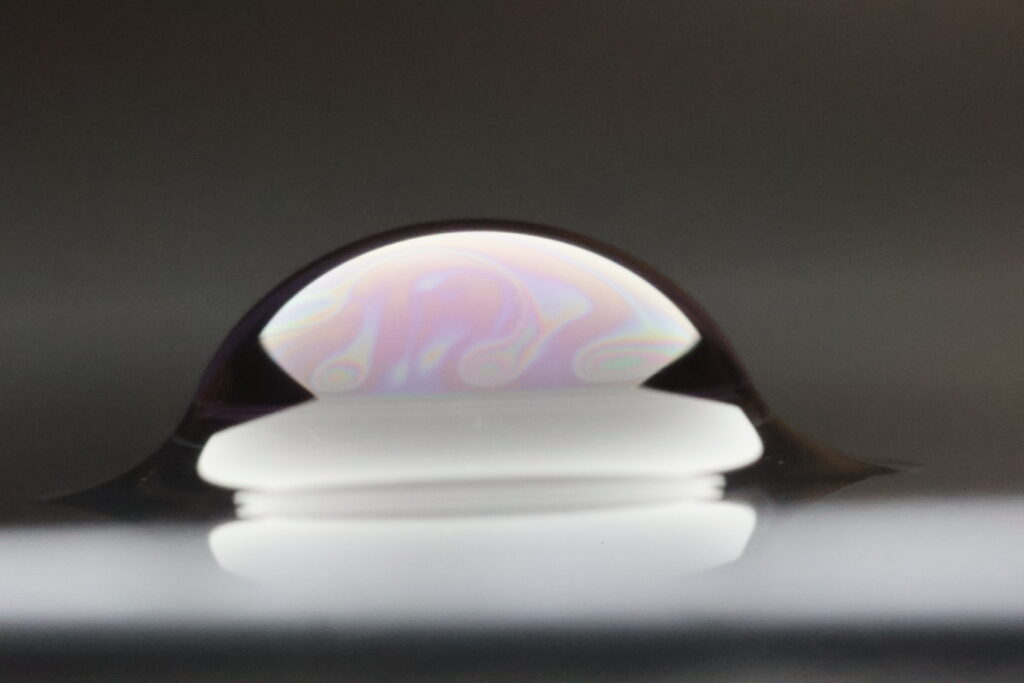

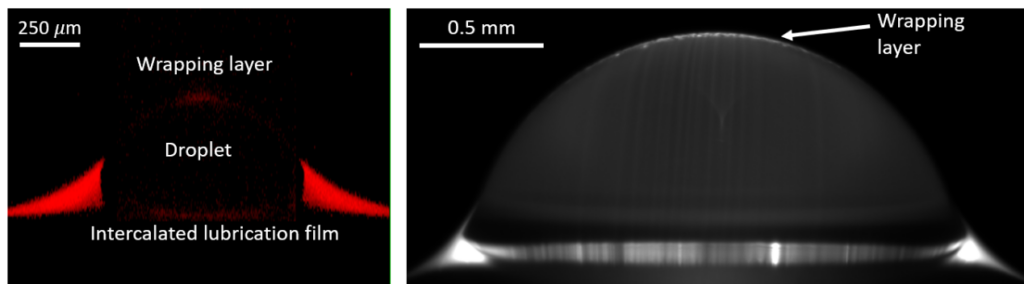

Wrapping/encapsulating oil layer characterization

Water droplets on slippery liquid-infused porous surfaces (SLIPS) or lubricant-infused surfaces (LIS) form a thin wrapping oil layer due to the interfacial forces. The presence of an oil film around droplets can affect the performance of SLIPS, including heat barrier effects on dropwise condensation. The wrapping layer is also a source of oil depletion of SLIPS. At ETL, we investigate the wrapping layer phenomenon and measure its thickness (around 100 nm) using the planar laser-induced fluorescent (PLIF) method. The PLIF method utilizes a purely optical setup for precise measurement and analysis.

Water droplets on slippery liquid-infused porous surfaces (SLIPS) or lubricant-infused surfaces (LIS) form a thin wrapping oil layer due to the interfacial forces. The presence of an oil film around droplets can affect the performance of SLIPS, including heat barrier effects on dropwise condensation. The wrapping layer is also a source of oil depletion of SLIPS. At ETL, we investigate the wrapping layer phenomenon and measure its thickness (around 100 nm) using the planar laser-induced fluorescent (PLIF) method. The PLIF method utilizes a purely optical setup for precise measurement and analysis.

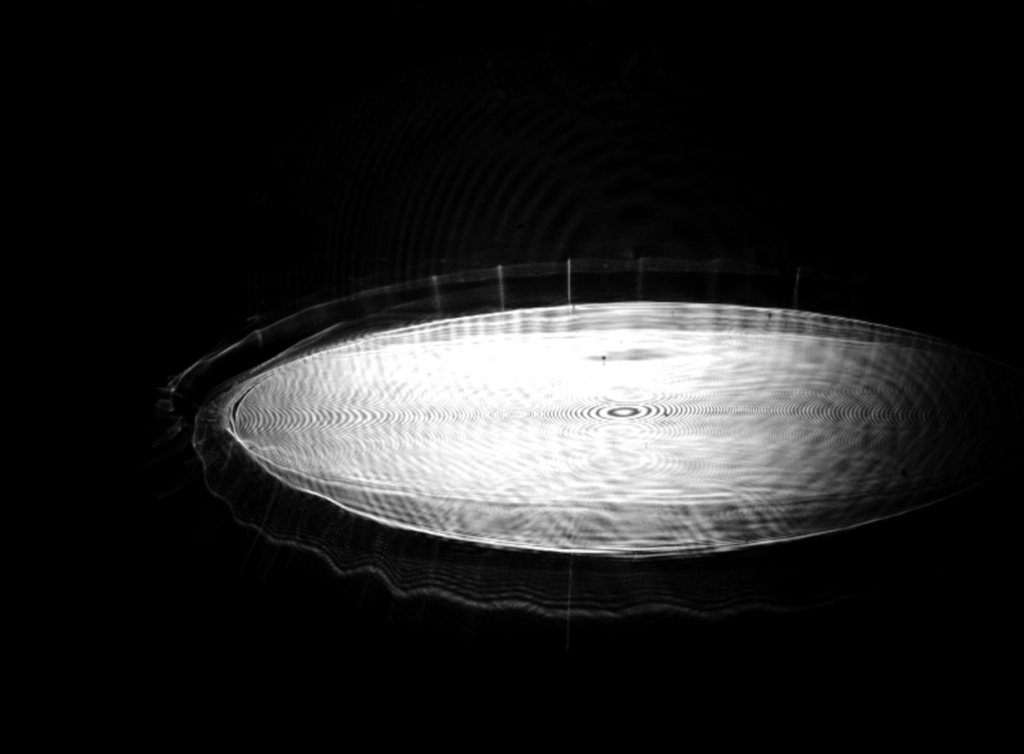

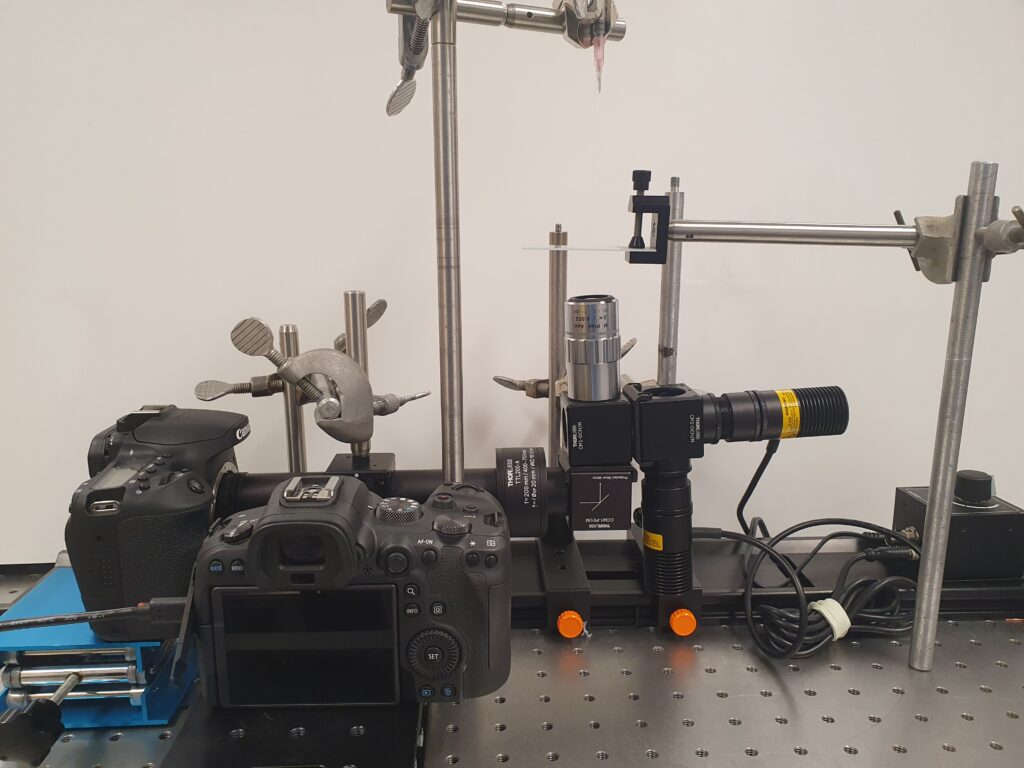

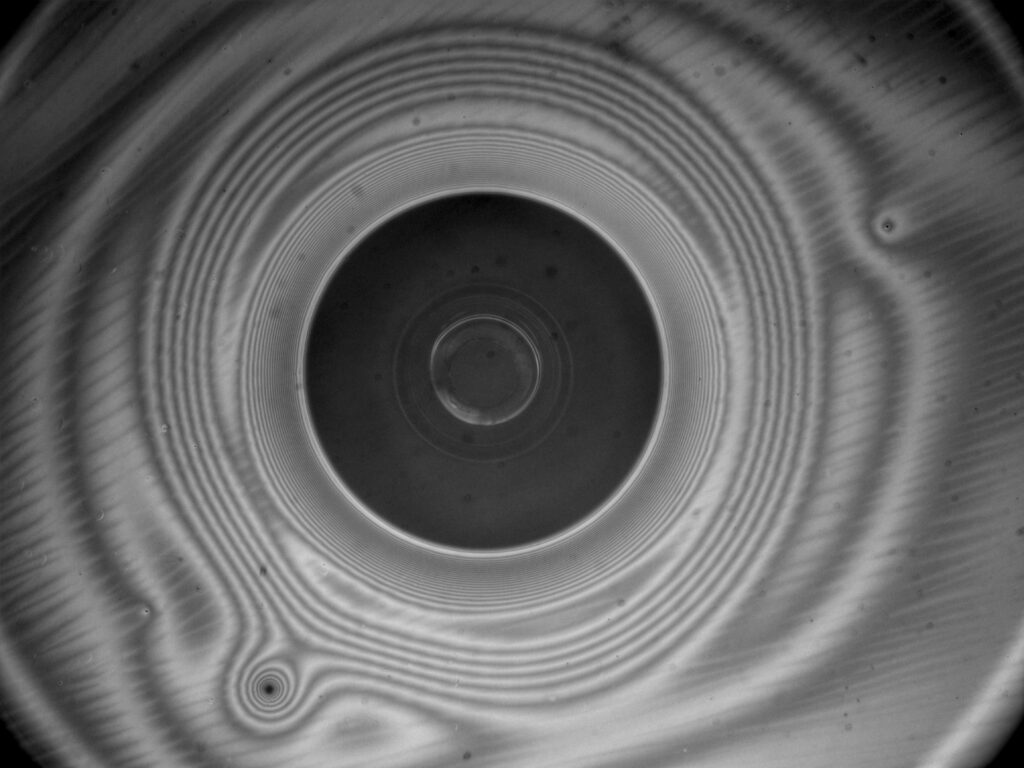

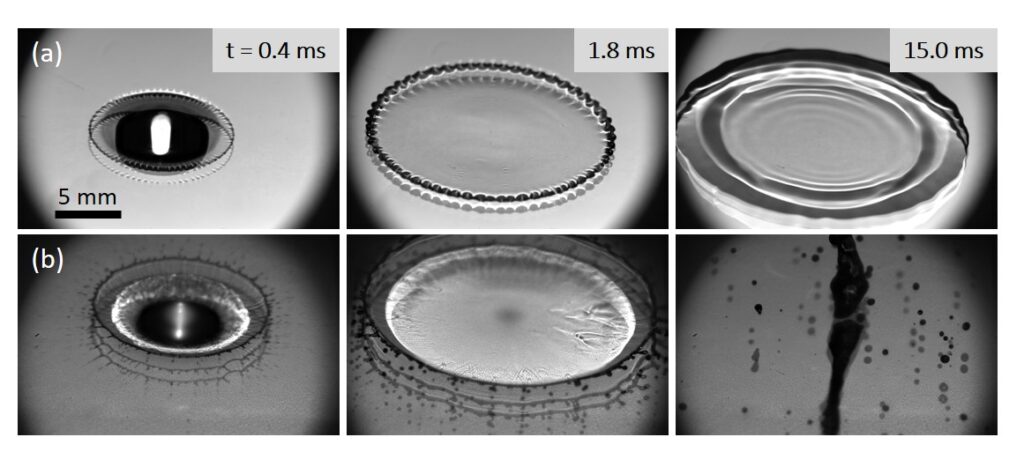

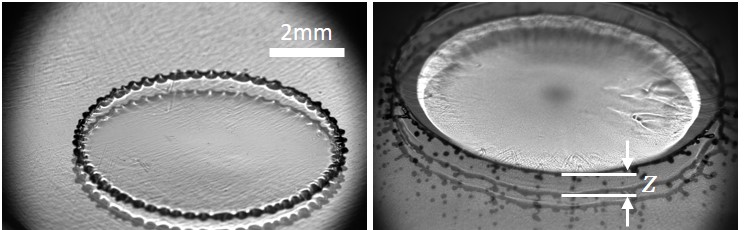

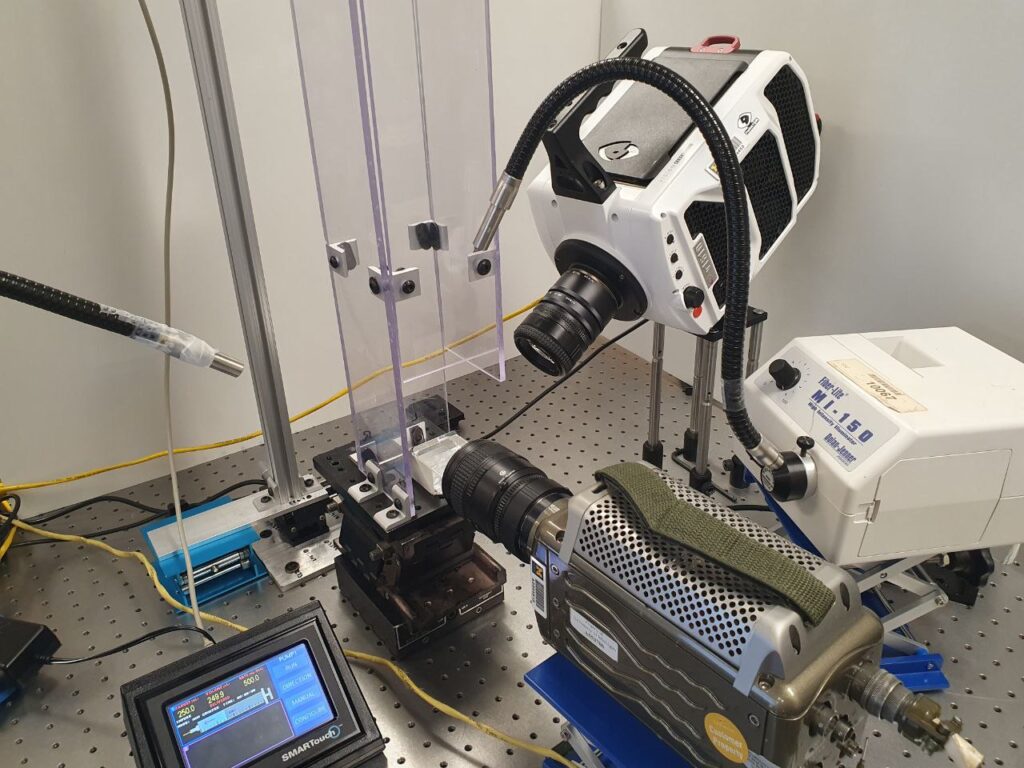

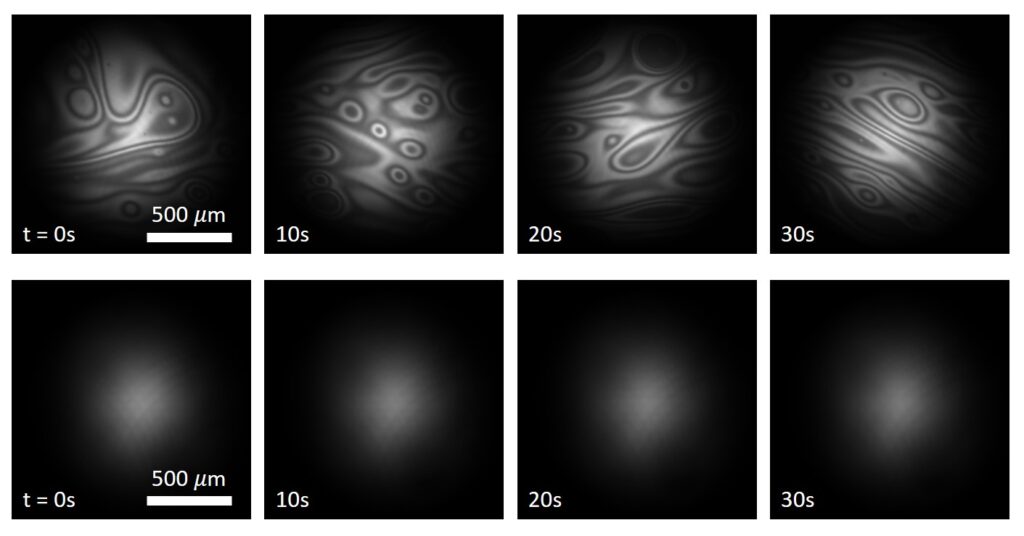

Droplet and thin film visualization. Characterization of entrapped air bubble during high-velocity drop impact.

Typically, during high-speed drop impact, we can observe several interesting phenomena ongoing. One of them is the entrapment of tiny air bubble inside the droplet, which has an important meaning for the whole scenario of the droplet impingement, especially on microstructured hydrophobic surfaces. With the use of the Brester angle setup, we can focus on different light intensities coming to the camera and properly describe selected regions of complicated air/water/solid interfaces. Moreover, we can estimate the thickness of the thin lamella film on the base of the intensity of light or interferometric fringes.